HOW THE RILEY HOPKINS 300 SCREEN PRINTING PRESS TRANSFORMED PARSONS DESIGN

Step inside the world of screen printing innovation and success as we dive into the incredible impact of the Riley Hopkins 300. This printing powerhouse has left an indelible mark on countless print shops, propelling them toward expansion and full-throttle growth. Today, we have a special treat in store for you as we sit down with Parsons Designs, one of the many shops that have harnessed the power of the Riley Hopkins 300. We've asked them a few questions to get an insider's perspective on how this remarkable machine has transformed their business. Let's hear their story and discover the secrets behind their success.

#1: HOW DID YOU GET STARTED?

I did my first screen print in 2007 at a local community college with a wooden screen clamped to a board with hinges. I was printing on paper at the time, just trying to mass-produce and re-create my own artwork. I later found out you could screen print on t-shirts and it was at that moment my whole life changed.

I play guitar for a local rock band and started designing the swag that we would sell at shows. Now I knew of a good way to make t-shirts, but I didn't know about the screen printing press. I called a local print shop and went to see the press in action. This print shop needed help with other print jobs, so I knew how to screen print and we traded band shirts for help around this print shop.

I fell in love with the shirt printing business. This shop had a 4 color 4 station workhorse press with no registration adjustments at the time. We later found a used 6 color 4 station Riley Hopkins press with joystick registration and we jumped at the opportunity and bought it. This press is great!

Now fast forward. Parsons Designs was started in 2012 in Salem, Oregon. Our mission is to help other business owners with a brand and image they can be proud of and to boldly wear on their swag for a professional look. Our Motto is “You are Designed to do GREAT Things.”

#2: HOW HAS YOUR EXPERIENCE WITH THE RILEY HOPKINS 300 BEEN?

We have been using the same amazing Riley Hopkins 6 color 4 station Joystick Registration press for over 15 years.

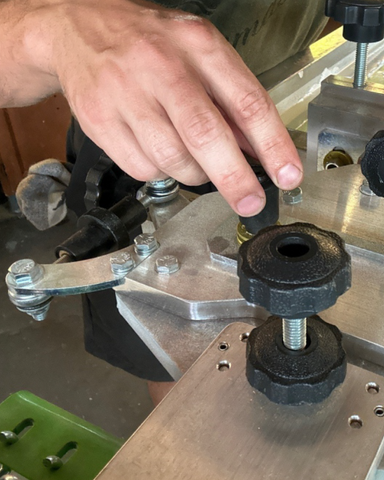

In 2022 we decided to upgrade to a Riley Hopkins 300 8 color 6 station press with micro registration and are so glad we did. With the growth and demand for more colors, we wanted to have the ability to have the micro adjustment to really dial in our multi-color prints. This press helps us do just that.

RELATED: WHAT IS MICRO REGISTRATION AND DO YOU NEED IT?

#3: WHAT DOES A TYPICAL PRINT RUN LOOK LIKE FOR YOU?

The most complex jobs we run are the 6 to 8-color prints. Just because of the setup time but once it's locked in and set up this press is ready to knock out some shirts. And if we have to make an adjustment, it's better to do so with the micro adjustments.

The largest job we have printed with this press is 1000 prints for a local run. With 2 or 3 people it is not too hard. With 1 printer, 1 shirt setter, and 1 stacker you can do a job this size in a 1 or 2-day shift and have fun while doing so. On our other Riley Hopkins 6 color 4 stations, our biggest job was a 3-color print for a Wildfire fundraiser to support the city of Detroit, Oregon, with about 4,000 to 5,000 shirts and sweatshirts printed.

Would we recommend this press? Absolutely! Anyone who has seen our shop or watched our YouTube channel knows we are proud of what we are able to produce with the Riley Hopkins 300 8x6 press.

RELATED: THE EVOLUTION OF RILEY HOPKINS AMERICAN-MADE SCREEN PRINTING PRESSES

A heartfelt thank you goes out to Parsons Designs for generously sharing their remarkable journey with the Riley Hopkins 300. Their success story is a testament to the endless possibilities that this powerful screen printing marvel offers. If you're ready to take your print shop to new heights, be sure to explore the Riley Hopkins 300 – the ultimate game-changer. And for a closer look at the incredible creations by Parsons Designs, don't forget to visit their shop and witness the magic firsthand. It's a world of endless potential waiting to be discovered!